By James Elliott – April 15, 2024

On the morning of April 15, 2013, at about 0900, the Emergency Response Team was called to the manufacturing floor for a medical emergency. When I arrived, the scene was horrific. An employee had suffered critical injuries after making contact to a rotating shift of a mixing machine. The employee had facial trauma, a broken right arm, abrasions all over his body, and worst of all, his legs from the mid tibia-fibula down were traumatically amputated. In addition, there was blood and bodily tissue all over the floor and walls and the employee’s feet had been thrown across the manufacturing floor landing about 25 yards away in two different directions. He was still alive.

Over ten years ago I worked as the Senior Manager of Engineering and Maintenance for a global producer of aerospace adhesive and composite materials. The scope of my initial role with the company was to lead the small group of process and facilities engineers as well as the maintenance department. With nearly 15 years of experience as an EMT with the US Coast Guard as well as various other industrial fire brigades, I was also a member of this company’s Emergency Response Team (ERT).

We did what we could for the employee given the situation and our limited resources. Because of my medical experience I took the lead in patient care until the fire department arrived, took over, and transported him to the hospital. During the day we received updates from the hospital that appeared positive. The next morning, we unfortunately learned that the employee passed away in surgery the previous afternoon due to internal bleeding. We were devastated.

The products made by this company, which has its headquarters in Germany, are used to manufacture all kinds of aircraft from airliners to stealth military fighters to missiles and rockets. Because it manufactures aerospace products, the production plant was certified under the AS9100 Quality Management System for Aviation, Space, and Defense Organizations. The plant was also certified under the OHSAS 18001 Occupational Health and Safety Management System (SMS) and the ISO 14001 Environmental Management System.

One would think with all of these ISO management system certifications for safety and quality, the plant would have a stellar safety and quality performance. Isn’t that the purpose of holding these certifications, to achieve outstanding performance in safety and quality? Unfortunately, this was not the case. The plant was riddled with occupational injuries and product quality escapes. To compound the situation, soon after joining the company I found the management staff siloed, confrontational, and divisive. On top of it all was the ever-increasing pressure from the corporate executives in Germany and customers to perform and hit production goals. Things were not going in the right direction.

In the aftermath of this fatal event the question was asked, “how can a manufacturing site, who has a formal safety management system that is certified by annual audits by a third-party registrar as well as frequent internal audits have a significant fatal incident.” The answer was simple. The safety management system, as well as the AS9100 quality management system, were not fully embraced by the site leadership. Nor was it promoted and enforced by corporate leadership. The leadership never baked the requirements of the management systems into their daily processes and routines. Instead, the management systems were treated like check the box compliance activities with enough work being done just in time to pass the required audits and keep the certificates. Had the management system been embraced and the leadership taken a more active role, things would have been different.

So what is a management system?

Simple put, a management system is the policies, processes, and procedures used by an organization to ensure that it can fulfill the tasks required to achieve its objectives. The system also includes how the different policies, processes, and procedures within an organization interact and work together to achieve the desired results. This includes how people in the organization are trained to have the required knowledge and skills to successfully execute the polices, processes and procedures.

There are many different management systems that have been developed over the years, each typically having a unique focus. Most are a voluntary certifications through a third-party registrar. Some are required by regulations. Below is a short list of the various types of management systems one may come across:

- ISO 9001 Standards for Quality Management Systems

- ISO 45001 Standards for Occupational Health and SMS (replaced OHSAS 18001 in 2018)

- ISO 14001 Standards for Environment Management Systems

- ISO 41001 Standards for Facilities Management System

- AS 9100 Quality Management System for Aviation, Space and Defense Organizations

- AS 9110 Quality Management Systems for Aviation Maintenance Organizations

- AS 9120 Quality Management Systems for Aviation, Space and Defense Distributors

- 14 CFR Part 5 FAA Regulations for Aviation Safety Management Systems (SMS)

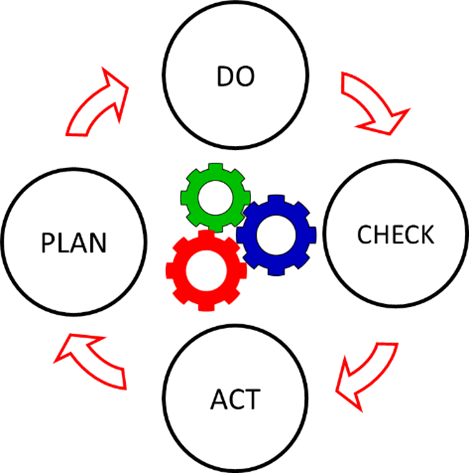

Modern management systems are designed to be dynamic and promote continual improvement in the organization. They typically follow the Plan – Do – Check – Act process approach.

Despite having different focuses, such as safety, quality, or environmental, all management systems whether they are regulatory safety mandates or voluntary quality certifications have the same basic components. The detailed requirements within each component may vary by certification type and focus, but the overall components are the same. These components are:

- Policy: The executive management’s commitment to the management system. This is where the vision and mission of the management system is spelled out.

- Objectives: The overarching goals of the management system. What will the management system achieve for your organization.

- Standards: The various manuals, SOPs, Task Cards, etc. that document the organization’s processes.

- Risk Management: Formal processes for recognizing, evaluating, and mitigating risk within the organization.

- Change Control: Formal control to changes to processes and documentation.

- Training: The formal processes and programs used to provide people with the knowledge and skills to follow and meet the requirements of the standards.

- Communications and Awareness: Various methods of communicating information within the organization and to external entities.

- Documentation: Includes the written standards as well as various production, safety, and quality records.

- Employee Participation: Programs such as employee safety meetings and employee reporting programs.

- Investigations & Root Cause Analysis: Robust processes for investigating, learning from incidents and audit findings, and generating effective solutions.

- Internal Audits: Auditing of the various management system functions to ensure they are working properly and providing the intended results.

- Measures: Organization’s various key performance indicators (KPIs). These KPIs are designed to measure how well the management system is meeting the defined objectives.

- Continual Improvement: Proactive activities to improve various aspects of the organization and its processes.

- Management Review: A periodic review of the management system by the leadership to ensure it is functioning properly and providing the desired results and meeting its objectives.

To understand how these different components of a management system work together, image the fan section of an aircraft’s turbofan engine (pictured below). The fan has two main components, the hub and the blades. All of these components perform specific jobs and are indispensable. The hub’s function is to hold all of blades together in the fan and to impart energy and motion to the blades. Without the hub, the fan blades would be useless. Using the energy and motion of the hub, the blades provide the force that moves air through the engine and propels the aircraft. All of the blades are important. If one is missing or damaged, the fan will be out of balance, which would have a catastrophic effect ripping the fan and engine apart.

In a management system the various components of the system are represented by the blades. Each one performing its specific function. All blades must be present and in balance with one another. If one component of the management system is missing, the management system becomes ineffective. It stops working with the results often being injuries, equipment damages, and quality escapes.

The leadership of the organization is represented by the hub of the fan. Just like the fan hub holds the blades together, leadership holds the management system together and gives it energy and life. When an organization’s leadership is not directly engaged with the management system and/or the management system is treated like a check the box compliance exercise, it’s like having a seized bearing in the fan hub. The fan doesn’t turn and the management system is ineffective. Again, potentially leading to injuries, equipment damage and quality escapes.

A lack of leadership engagement and active participation in the management system is by far the most common reason management systems fail to produce the planned results and achieve their objectives.

Lack of leadership engagement also has a negative impact on the safety and quality professionals in the organization who are tasked with maintaining the management system certifications. The frustration of trying to get leadership cooperation can be like trying to push a rope uphill. These employees are placed in a constant struggle to maintain the integrity of the management system, yet are often the first to receive blame when the management system fails and does not achieve its intended results.

So how can an organization’s leadership be better engaged in the management system? Here are three key things that need to happen.

Get Educated

The organization’s leadership needs to know their management system. Yes, they’ll have safety or quality professional who are experts in the details, but the organization’s leadership needs to have a foundational working knowledge of all components of the management system and how they work together to achieve results. They need this knowledge to be able to coach and mentor their team members in the use of management system to achieve the organization’s goals.

Drop Safety and Quality

Most formal managements system have either a safety or quality focus to them. This is usually results in leadership getting hung up on these categories and only applying the management system to them. I’ve lost count of the number of times I’ve leaders say, “We don’t need to conduct a risk assessment because this is a business decision, not a safety one.” This kind of thinking leads the managements system to become a check the box exercise for passing periodic audits.

Instead of having such a narrow focus, the components of the management system need to be baked into the daily business processes of the organization. A management system is not a “program.” It must become part of the culture of how the organization does business.

It should be noted that any organization can establish a management system. You don’t need to go through a lengthy and expensive certification process if it’s not required. You can however adopt the best practices of a management system in your organization.

Own it

In addition to having knowledge of the system and incorporating it into the organization’s everyday business operations, an organization’s leadership needs to own their management system. Again, they’ll have the support of the safety and/or quality department personnel who will attend to much of the day-to-day monitoring of the management system, but the leadership needs to be fully engaged. From the establishment of the management policy to personally leading the management review meetings, the leadership of the organization must take full accountability for the operation of the management system and ensure that the system is working to achieve the organization’s goals.

If the leadership of an organization does these three things, they will give their organization’s management system the energy and motion it needs to be fully functional and achieve its purpose. Then, and only then, will the organization be able to mitigate the risk of tragic events like the one my former company experienced on April 15, 2013.